The BackSpacer has become our best selling product over the years since we added them to the 420EDC shop. From time to time, folks relay feedback by review, social media and direct communications. Much of this comes down to fit and and function of the design. "They fall right out" or "They fit loosely" sums it up briefly.

By design, BackSpacers are designed to fall right out and they are designed to fit loosely. We don't hide this fact in the product description of the BackSpacer. Here is our reply to someone relaying some feedback on Reddit:

The only time a BackSpacer should be falling out of a stem is when you have it withdrawn from the device post-session & you are unloading the stem. Gravity does the rest of the work during loading by lowering the device onto an inverted stem to load. Fill the entire stem with flowers & the BackSpacer setup you decide. Insert the stem to the base of the chamber (no 1mm gap necessary).

For instance we use a 5mm BackSpacer in the Solo III with the XL stem. Then load a standard load of flowers (about 9mm worth) & drop a second 5mm BackSpacer on the end after tamping the flowers. It lifts the load away from the heater core at the base of the chamber & preserves flavor compared to using the OG Chamber & having the flowers closer to the heat.

When you are done post-session, lift the device upwards off the stem, so you are looking at the loaded chamber with the mouthpiece facing downward. Emptying at this point should be where you have the BackSpacer on the end of the stem fall out (assuming you use one on the end), a 5mm for us in the paragraph above. Lots of folks use the 2mm screen on the end or the 3mm.

Check the Solo III chamber post session & if you find any bits of flower that fell to the base, empty it before it cools (it can stain the chamber & is harder to dislodge if allowed to cool on the steel).

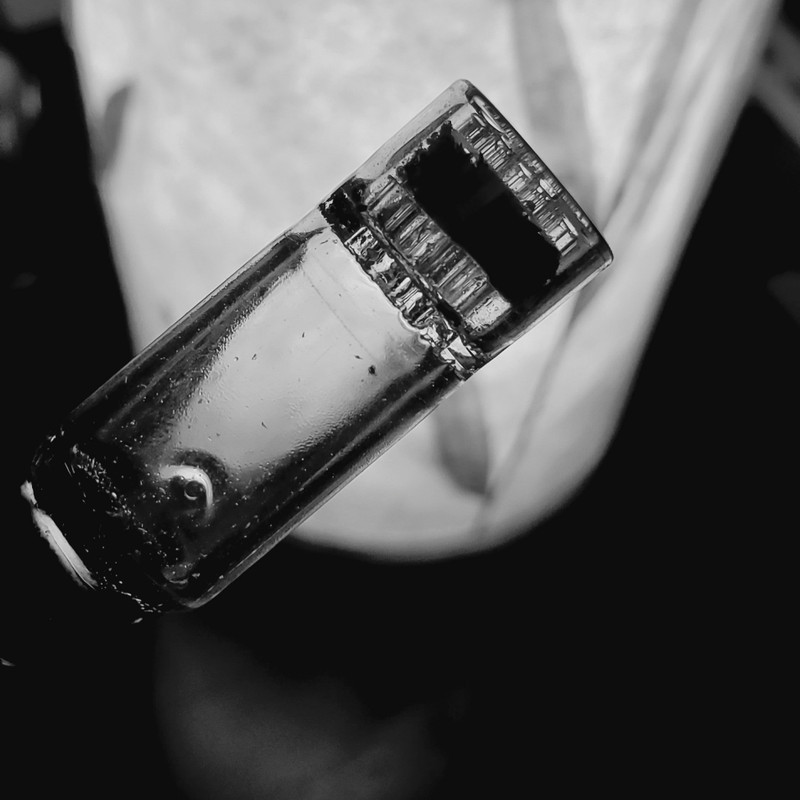

BackSpacers are designed to fall right out, otherwise you may have to break them (if glass, Titanium wins vs borosilicate) or the stem's chamber to dislodge stuck glass inside the chamber that wedges in at a bad angle. Also, the standards for the internals of the glass varies more than the outer diameter which is where the precision is focused while molding during production. This is another reason they need to have a loose fit.

In early 2025, 420EDC released the BackSpacers in Grade 2 Titanium for the Arizer Solo/Air dimensions. These were inspired by the Borosilicate Glass BackSpacers which achieved Best Seller status in 2024. The functionality is the same with differences between the two materials. Titanium conducts heat better and the holes are tapered with the titanium BackSpacers. Borosilicate doesn't conduct heat as well and the holes are more uniform from side to side of the cut glass.